Insert Molding

Taurus Engineering insert molding capabilities are used to create a finished product by combining two or more components. The process involves inserting a pre-manufactured component or object, such as a metal or plastic part, into a mold cavity, and then injecting molding the required resin around the insert to create a single, finished part.

The advantage of insert molding is that it allows Taurus Engineering to create parts that have multiple materials or components, without requiring assembly or additional manufacturing steps. It is commonly used in the production of items such as medical device connectors, infusion sets, IV catheters valve swivels, medical heat and moisture exchangers and wind variety of medical devices.

Insert molding can be done using a variety of molding techniques, including injection molding, compression molding, and transfer molding. Taurus Engineering will make the best choice on a variety of factors such as the complexity of the part, the volume of production, and the desired properties of the finished product.

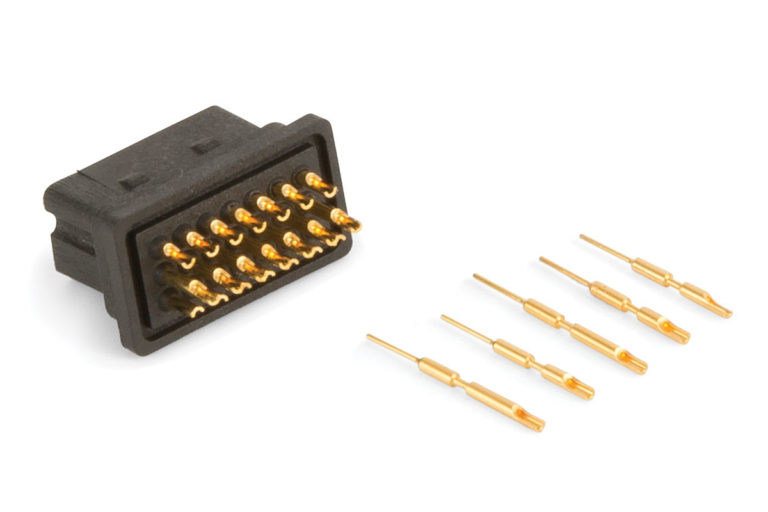

Insert molding example:

Medical Device Connector utilized in the Nero market with 21 overmolded gold plated 0.068” diameter pins. A Multi cavity tool was designed to accomplish the specified assembly. Taurus Engineering designed automation around the process using bowl feeder systems accompanied with a robotic system placing pins into the mold for maximum productivity.

Soft Touch Overmolding

Why use soft touch overmolding? A key reason is that an overmolding design improves the overall aesthetic design and functionality of a product. Soft Touch overmolding is an injection molding process Taurus Engineering uses to create products that have a soft and comfortable exterior surface. This involves the application of a soft, rubber-like material, typically a thermoplastic elastomer (TPE), over a rigid plastic or metal substrate. The process creates a seamless and durable bond between the two materials, resulting in a product that has improved grip, cushioning, and impact resistance.

Taurus Engineering has perfected the process which involves several steps, including the preparation of the substrate material, the molding of the soft touch material onto the substrate, and the curing of the material to form a strong bond.

The substrate is typically first molded into the desired shape and then coated with a release agent to prevent the soft touch material from adhering to it. The TPE material is then heated and injected onto the substrate, where it flows around the contours of the surface to create a uniform coating. Once the molding is complete, the product is cured to create a strong and durable bond between the two materials.

Common reasons to use Soft Touch Overmolding:

- Creates a soft grip surface around a part of the separate material

- Multi-color options for aesthetic impacts

- Adds flexible areas to a rigid part

- Eliminates assembly time

- Composites one part inside of another without fasteners or adhesives.

- Ideal for a wide range of medical components and devices

Overmolding example:

Handle set for comprised of many components using multiple materials and many value-added assembly operations.